Precision Machining

Ensuring Quality at

Every Process Step

High-precision metal parts require more than a final inspection—they demand in-process checks at every stage. At Daiko Seiki Manufacturing, we perform precise measurement and verification throughout the workflow to eliminate defects early. Backed by experience supplying metrology manufacturers, we deliver stable, repeatable quality.

Inspection Scope

We select the optimal inspection methods for each material and machining process.

From appearance and dimensions to threads and post-finishing condition, we execute rigorous checks to ensure consistent quality and peace of mind.

-

Appearance Inspection

Visual inspection; surface-roughness tester

-

Dimensional Inspection

Calipers

Gauges

Micrometers

3D Measuring Machine

Image Measuring Machine

Others

-

Post-Finishing Inspection

Appearance Inspection

Dimensional Inspection

Quality Control Standards

We maintains clear internal quality standards to ensure consistent quality across all products. We perform periodic calibration of measuring instruments and rigorously record and retain inspection data to enable reproducible accuracy verification. Measurements are taken in an environment controlled at 20 °C ± 1 °C to minimize external factors that could affect machining accuracy.

-

We are also preparing to obtain ISO 9001 certification

The international standard for quality management—to further strengthen reliability and our quality assurance system.

Process Assurance

We don’t rely solely on end-of-line inspection; we implement process assurance, a system that guarantees the manufacturing process itself. By defining clear work standards for every employee and enforcing compliance, we prevent defects upstream and achieve stable quality and reliable delivery.

-

Rationale

Product quality is not secured only by the final inspection result; it is built through the accumulation of each daily task. A mechanism that assures the accuracy of the process itself is therefore essential.

-

Implementation

We set explicit work standards for every process and establish a company-wide system to ensure adherence. This reduces dependence on individual skills or experience and maintains a stable level of quality.

-

Value to Customers

Process assurance reduces the risk of defects and rework, prevents delivery delays and quality variance, and establishes a stable supply framework—enabling a partnership you can trust.

From Inquiry to Delivery

We handle everything in-house—from first contact to final delivery. We listen carefully to your requirements and manage design, production, and inspection with discipline, so you receive high-quality parts on short lead times with confidence.

-

01. Inquiry

Contact us by phone or via the web form. Our specialists will respond quickly and clarify your needs and challenges.

-

02. Quotation & Order

Based on the information provided, we present the optimal quotation. Upon approval, we accept your order and move into preparation.

-

03. Process Planning

Using our production control system, we define a clear manufacturing flow—eliminating bottlenecks, waste, and variability across all processes for efficient, stable progress.

-

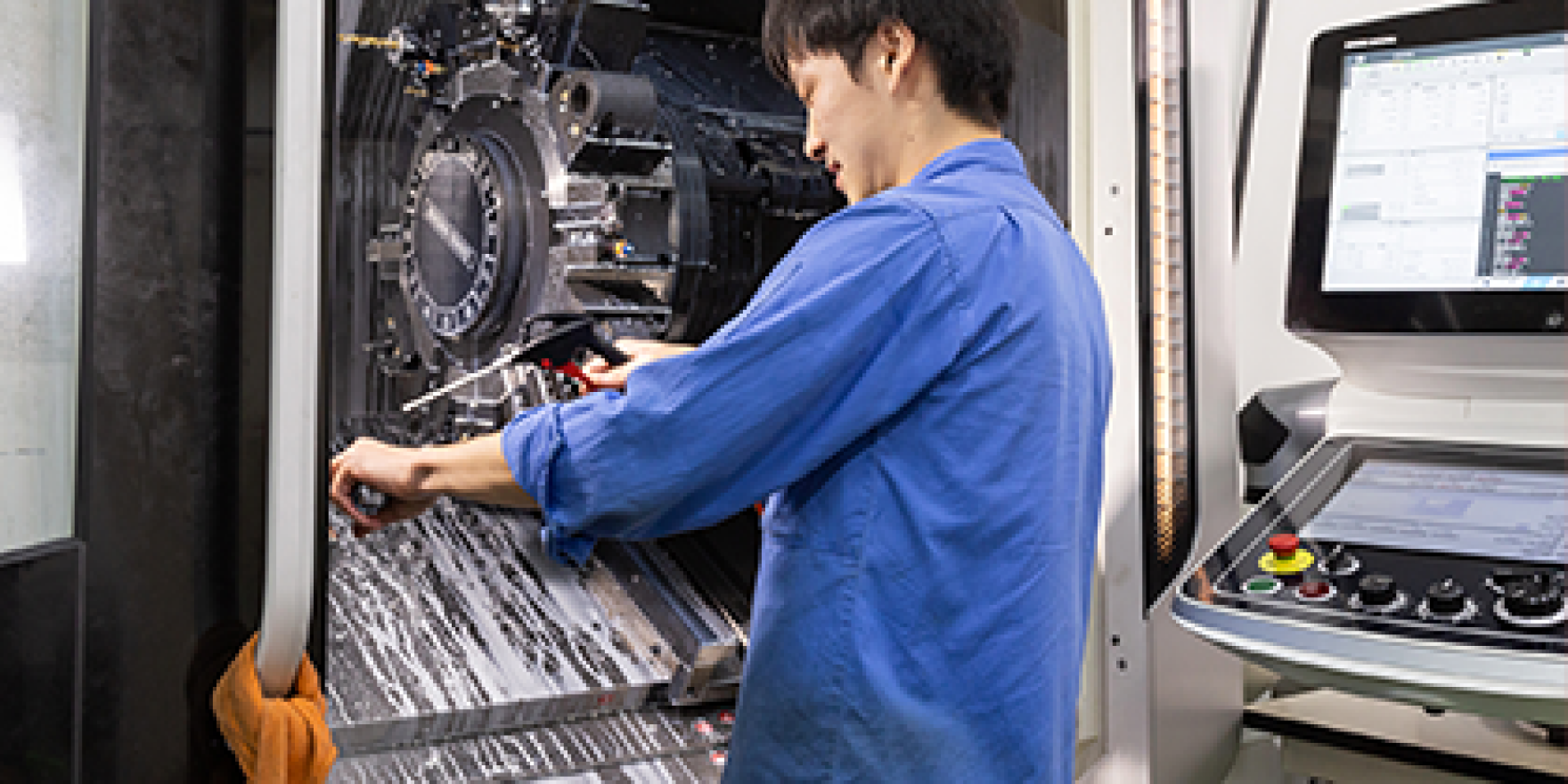

04. Production

CAD/We generate precise CAD/CAM programs and machine the parts using machining centers, CNC lathes, welding, and more. Because every step is in-house, we respond both quickly and reliably.

-

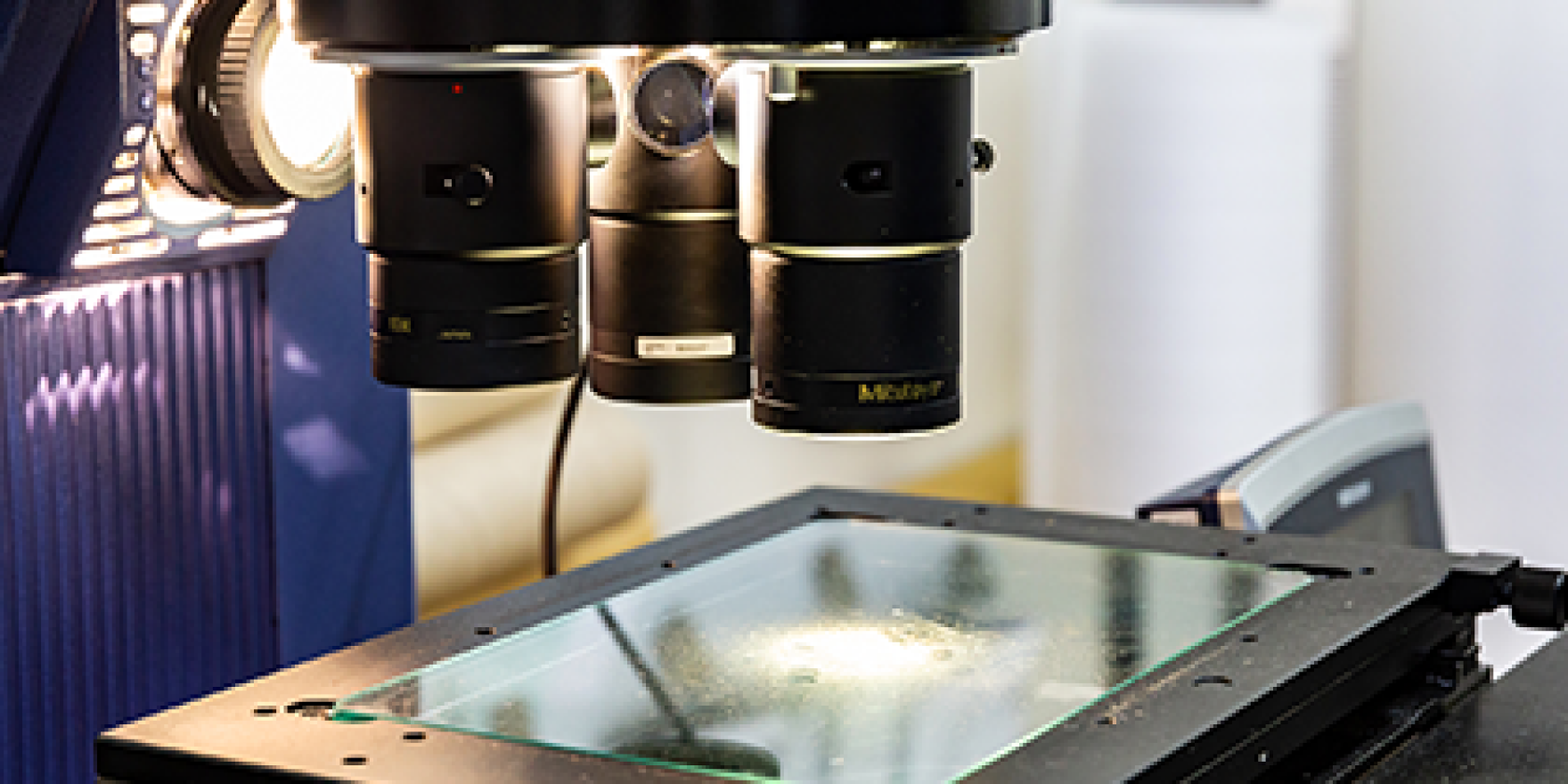

05. Quality Inspection

Under rigorous standards, we perform thorough checks with precision measuring instruments. Leveraging know-how built through deliveries to major manufacturers, we ensure consistent quality.

-

06. Shipping & Delivery

Each finished part is carefully packed and undergoes a final check before shipment. We take responsibility end-to-end so you can receive your order with confidence.

In-House Delivery Service

-

Coverage: Tokyo’s 23 wards, Yokohama City, Kawasaki City

We operate two company trucks for direct delivery. In-house transport shortens lead times and enables fast, reliable hand-offs. Note: Coverage may vary depending on size and quantity.

Delivery Area

Tokyo (23 wards)

Adachi | Koto | Arakawa | Setagaya | Itabashi | Taito | Edogawa | Chiyoda | Ota | Chuo | Katsushika | Toshima | Kitakyushu | Nakano | Koto | Kita | Minato | Shinjuku | Meguro | Shibuya | Shinjuku | Meguro | Shibuya | Shinjuku | Meguro | Shibuya Ward

Yokohama (Kanagawa Pref.)

Tsurumi | Kanagawa | Minami | Konan | Bao-kayagaya | Asahi | Isogo | Koukitan | Aoba | Tsuchiura | Izumi | Tsuzuki | Yokohama | Kawasaki | Takatsu | Miyamae | Atsugi Ward

Kawasaki (Kanagawa Pref.)

Kawasaki | Kouenji | Nakahara | Takatsu | Tama | Miyamae | Atsugi Ward