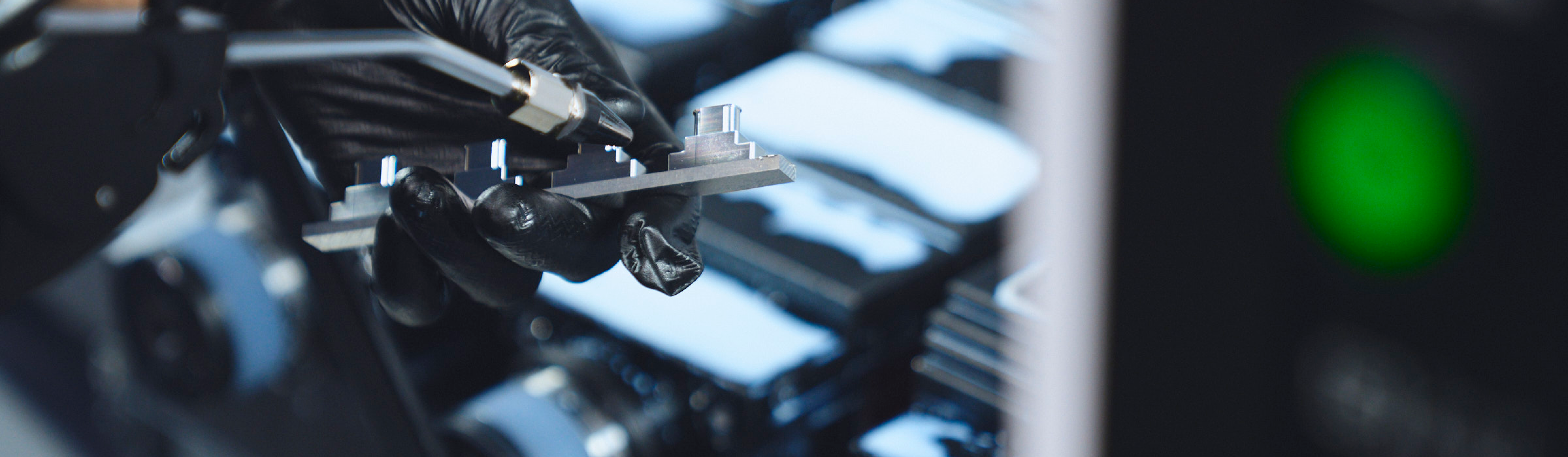

Precision Machining

Business

Reliable,

end-to-end expertise—from large parts to small.

From machining and turning to welding and large-format cutting, our integrated in-house setup balances speed and precision.

Mill-Turn Machining

Combining turning and milling to machine complex geometries efficiently and with high precision.

From precision work on 3-axis machining centers to 5-axis machining for complex shapes, we cover a wide range. Leveraging rotary and tilt axes, we finish previously difficult geometries with high accuracy in a single setup. We enforce rigorous process control through to surface treatment and final finishing, ensuring consistent end quality. In-house, we run regular training sessions to pass down and strengthen veteran know-how. From prototyping to mass production, we deliver stable, repeatable quality.

Industries We Serve

5-Axis / 3-Axis Machining

Centers

High-precision machining for complex geometries

From precision work on 3-axis machining centers to 5-axis cutting for complex shapes, we cover a wide range. By leveraging rotary and tilt axes, forms that used to require multiple setups can be finished in a single setup with high accuracy. We enforce rigorous process control through to surface treatment and final finishing, ensuring consistent end quality. In-house, regular training sessions pass down and strengthen veteran know-how. From prototyping to mass production, we deliver stable, repeatable quality.

Industries We Serve

CNC Turning

Stable quality through

high-precision turning

Our CNC lathes excel at shafts and cylindrical parts, handling everything from mass production to prototypes. Alongside the stable accuracy of automated control, Daiko Seiki Manufacturing applies the expertise of skilled technicians to flexibly tackle difficult parts and complex process flows. We support the precision turning needs of diverse industries, including XXX, XXX, and XXX.

Industries We Serve

Welding

Skilled welding that balances

precision and strength

At Daiko Seiki Manufacturing, welding is centered on the craft of experienced technicians, achieving both high precision and high strength. With minimized distortion and misalignment, we deliver consistently stable finishes across a wide range of applications—from XXX to XXX. We flexibly support prototypes through mass production, meeting your quality requirements.

Industries We Serve

Large-Format Machining

Industry-leading large-part capability that balances precision and speed

At our Fujisawa Plant, we machine large parts up to 2,500 × 4,000 × 1,500 mm. With five-face machining on a bridge-type machining center (OKUMA MCR-A5CII), we finish complex and multi-process components with high precision. We supply high-quality large parts to a wide range of sectors, including rail, defense, and machine tools.

Working closely with the Kawasaki Head Office, we provide a one-stop service from small to large parts. A daily shuttle between Kawasaki and Fujisawa keeps workpieces moving smoothly and reduces inter-process coordination, enabling faster production and stable delivery. Building on our metrology-component know-how, we conduct inspections at every stage to maintain a reliable quality assurance system.